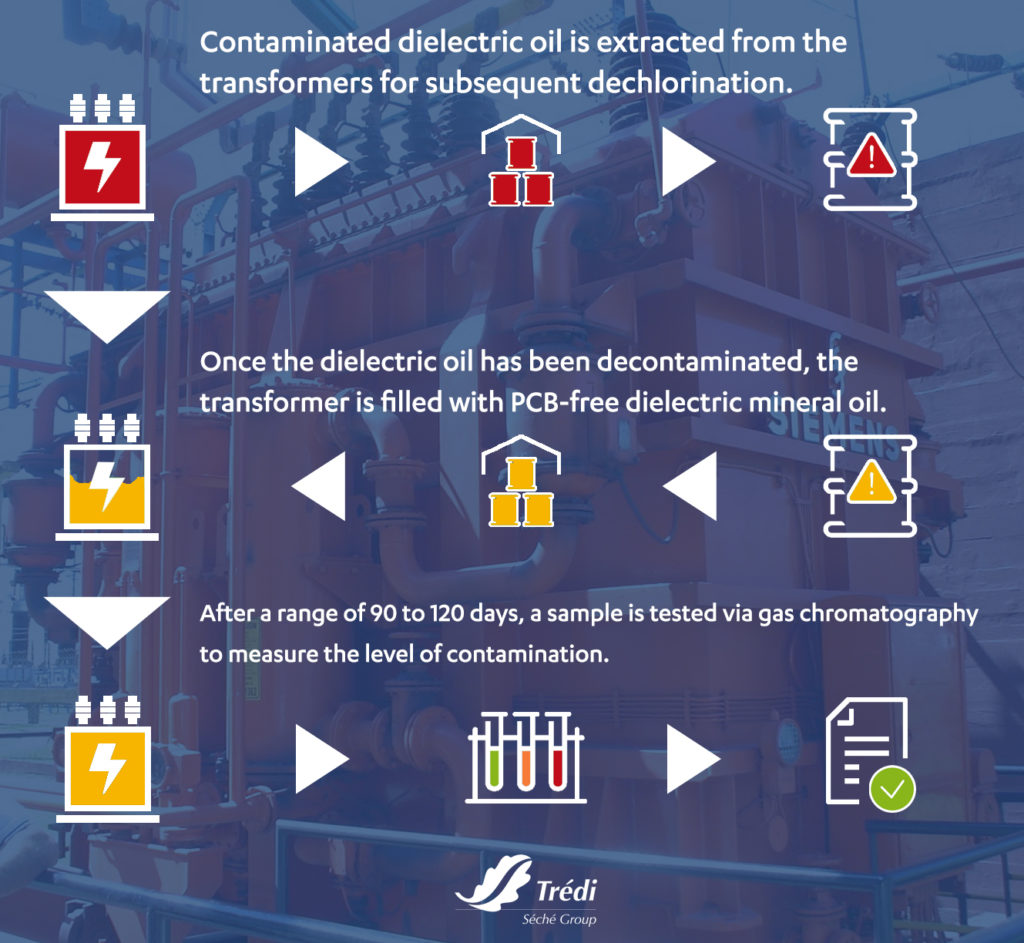

“Retrofilling” is the process by which transformers can be decontaminated without removing them from the substation or site where they are located. This method consists of emptying the transformer and filling it with dielectric mineral oil free of Polychlorinated Biphenyls (PCB) (<2ppm).

After a minimum of 90 days, the expected recontamination is approximately 10% of the initial PCB concentration.

How is it done?

- The transformer oil is analyzed to determine the PCB content (Gas Chromatography).

- The transformer is de-energized (without removing it from the site).

- The transformer is emptied trying to extract the maximum possible volume (exclusive pumps and hoses for PCB contaminated oils).

- The contaminated oil is packaged in identified drums for subsequent dechlorination.

- The transformer is filled with new dielectric mineral oil that meets the standard conditions.

- The transformer is re-energized.

- After 90-120 days of the procedure, a sample is taken for gas chromatography to check the results.

In transformers with less than 500 ppm contamination, the final result will be less than 50 ppm.